Taicang DELTA Precision Tech. Co.,Ltd.

Laser Micro-cutting

Laser Micro-cutting

无法加载取货服务可用情况

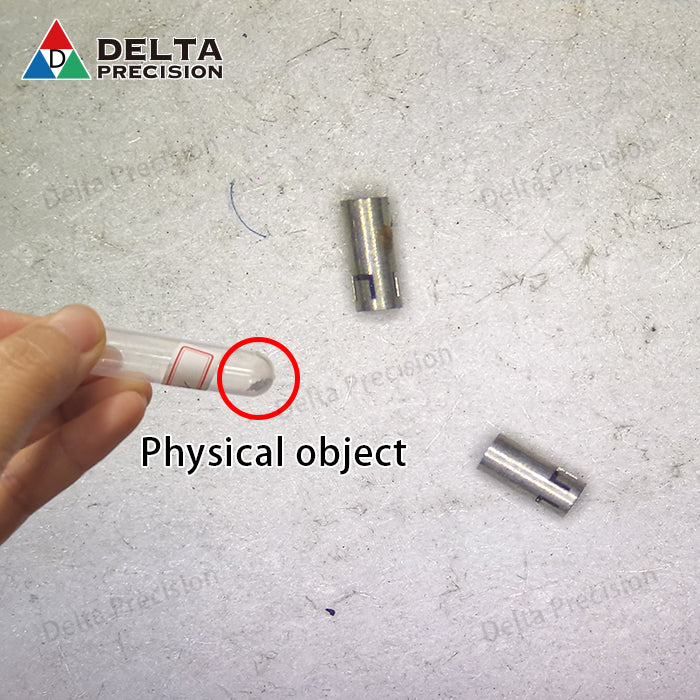

Micro laser cutting is a cutting-edge technology in the field of precision machining, which uses high energy density laser beams to cut materials with micron precision. The core principle is to achieve sub-micron notch width and feature size machining with a minimum of several microns through ultra-short pulse laser (such as femtosecond, picosecond laser) or high precision continuous laser, combined with precision optical system and numerical control platform. The technology uses a non-contact processing method with a minimal heat-affected zone, which is especially suitable for precision machining of brittle materials (such as glass, ceramics) and ultra-thin metals (thickness <0.1mm).

Technological advantage

High precision: positioning accuracy up to ±1μm, notch roughness Ra<0.5μm;

Multi-material adaptability: It can process stainless steel, titanium alloy, semiconductor, polymer film, etc.

Complex structure forming: Support three-dimensional micro-structure processing such as special-shaped holes, micro-flow channels and biomedical scaffolds;

Processing efficiency: Cutting speed up to 300mm/s (depending on material thickness).

Typical application

• Electronics industry: FPC flexible circuit board precision cutting, chip packaging

• Medical equipment: laser cutting for surgical instruments, vascular stent carving, surgical blade micro hole processing,precision laser cutting parts for medical devices

• Optical components: sapphire substrate cutting, diffraction optical components (DOE) manufacturing

• Aerospace: turbine blade gas film hole processing, MEMS sensor microstructure forming

Materials

· Metals & alloys

· Plastics

· Nitinol

· Tungsten

· Sapphire

· Ceramics

· Silicone

· Thin films

Our Manufacturing Technique:

Our Inspection Equipments:

Our Workshops:

Our Company Certificates:

If you need high-pressure cleaning nozzle, please contact us and we will customize a precise processing plan for you.

Share